Supply Chain

Build Resilient Supply Chains With Supplier Relationship Management (SRM)

Learn how to build resilient supply chains with Supplier Relationship Management (SRM). Discover strategies, best practices, and key concepts for effective SRM to enhance supply chain resilience. Optimize supplier relationships and strengthen your supply chain operations.

By India Index

7 min read

Supplier relationship management (SRM) is an umbrella term that defines how an organization handles its relationships with suppliers, vendors, manufacturers, and wholesalers.

Strong supplier relationships can optimize service quality, procurement costs, and supply chain resilience. For a long-term collaboration, organizations must ensure that the relationship with the suppliers benefits both parties. The right approach can enable enterprises to reduce procurement costs, improve quality, and build resilient supply chains.

This article will discuss everything you need to know about supplier relationship management, including its components, challenges, and best practices. By the end of this article, you will be able to understand a business from an SRM leader’s perspective.

Goals Of Supplier Relationship Management

Supplier relationship management is a proactive approach to building positive relationships with suppliers, as it can have cascading effects on the supply chain. The SRM leaders extract maximum value from their suppliers by offering value to them in return.

The modern integrated supply chain needs strategies that extend beyond cost-reduction tactics. The SRM strategies must support the business in identifying and benefiting from untapped business opportunities.

About 85% of the companies deal with supply chain disruptions. A two-way and mutually beneficial relationship between an enterprise and its suppliers can add great value to the firm. The primary goals of any supplier relationship management process are:

- Reduce costs and look beyond traditional sourcing efforts

- Drive and monitor the performance of suppliers and partners

- Expand transparency of supplier relationships

- Manage supplier risks with responsible sourcing and ethics

- Ensure compliance with local and international regulations

- Foster innovation and business development

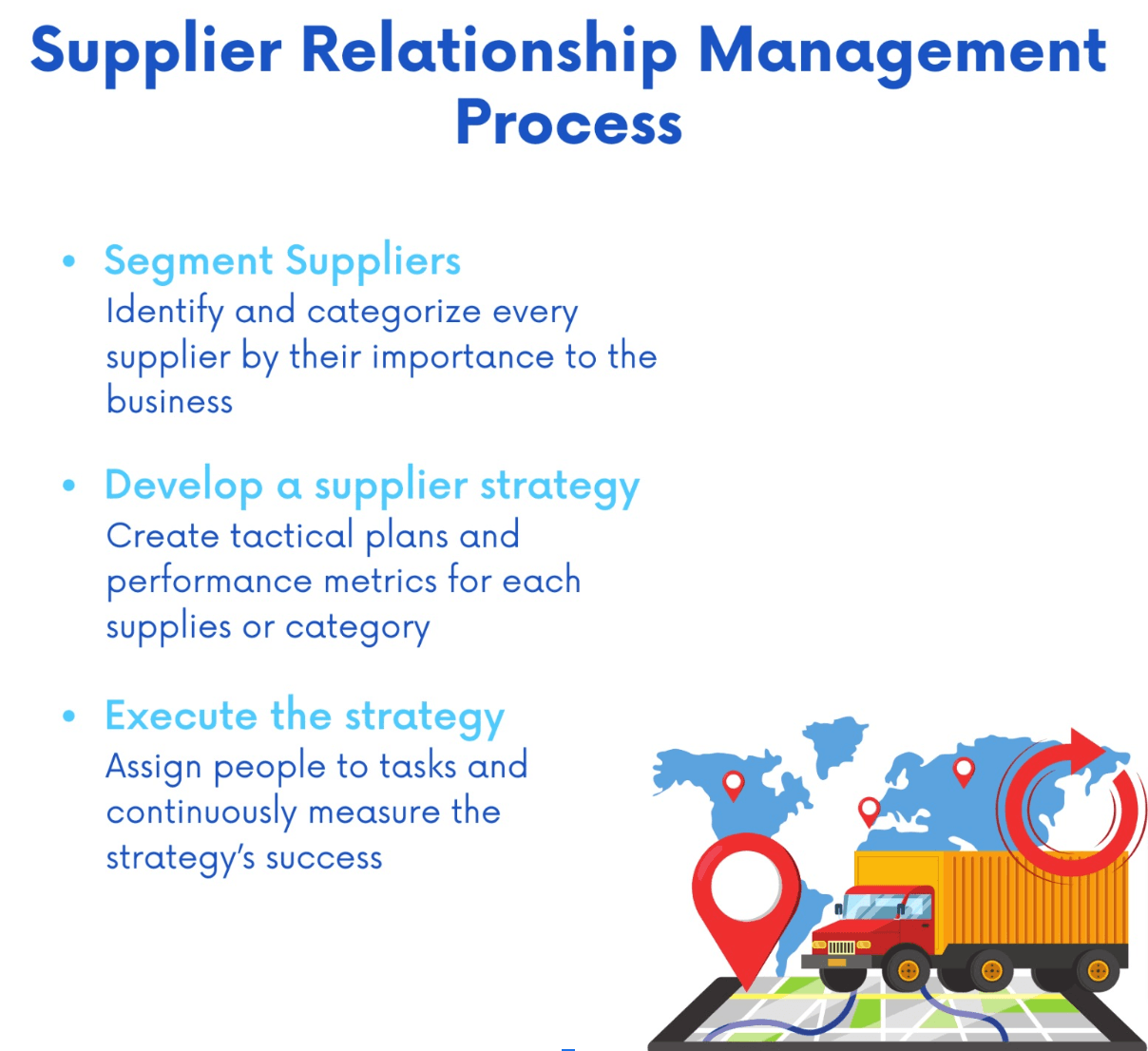

Components Of Supplier Relationship Management Process

The primary purpose of an SRM process is to identify critical partners and maximize benefits while minimizing supply risks. Nurturing relationships with important suppliers is essential for businesses to reduce time-to-market and improve product quality. Businesses must also create metrics to monitor and track supplier performance to offer more value to business partners that bring success. There are three basic components of the SRM process:

Segment Suppliers

Businesses that need supplier relationship management often work with a few suppliers at a time. To distribute risks, no business should rely on specific suppliers. However, handling too many suppliers can result in poor product quality. So, businesses must start with identifying and segmenting suppliers into different categories based on the value they bring to the business.

Leaders must develop metrics to help determine each supplier's risks and profit potential. Segmentation should be done based on the nature of supplier products and services, the amount spent on suppliers, and innovation potential.

Businesses only need to focus on nurturing their relationships with critical suppliers. This will bring down the cost of SRM and enable businesses to build strong and personal relationships with important partners.

Create Supplier Strategy

Once key suppliers are identified, leaders must build a strategy demonstrating their importance in the business supply chain. The strategy must benefit the buyer and supplier. Even though the focus must be on impactful suppliers, less critical suppliers should be addressed. Developing a supplier strategy involves identifying objectives, determining supplier budgets, onboarding suppliers for maximum efficiency, and incorporating analytics to track and monitor supplier performance.

Execute Supplier Strategy

The SRM process is not a one-time setup. Like any other process in an agile business environment, supplier relationship management should also be an ongoing process where the supplier performance is constantly matched against objectives. The supplier strategy should be monitored and adjusted based on the results it brings in. If necessary, newer tactics must be employed to ensure a strong supplier relationship. Suppliers will be interested in offering discount rates and participating in innovation if they feel valued.

Challenges In Supplier Relationship Management

In the evolving supply chain logistics, businesses must update their supplier relationship practices to stay competitive. As the world of ecommerce expands and super fast delivery is a differentiator for businesses, finding the right suppliers is key to success. The logistics industry disruptions and changing geopolitical and economic conditions push organizations to face new challenges.

Scarcity Of Materials

After the global COVID-19 pandemic, the material scarcity remains a challenge. The supply needs to meet the increase in customer demand. Suppliers, too, are struggling to bridge this gap as there is limited availability. Suppliers face wide-scale shortages and long lead times. They also have difficulties in finding the right transportation partner. Businesses must optimize their working capital to deal with downtimes, especially during peak seasons.

Increasing Freight Costs

Suppliers always seek cost-effective freight partners to meet their growing consignment needs. The increase in ecommerce sales has resulted in a higher demand for raw materials and manufactured goods. As a result, suppliers are looking for larger containers to ship their products.

However, shipping companies with limited shipping capacity cannot meet the increased demand. This has resulted in a sharp hike in the freight costs. For example, the freight prices from China to West Coast have increased by 240%. The impending economic crisis and rising inflation rates also result in climbing costs.

Forecasting Demand

The market volatility has made it difficult for the supply chain management to forecast demand properly. The supply chain industry has yet to recover fully from the pandemic disruptions, as the forecast numbers were skewed after a global event.

At any given time, forecasters cannot determine the right amount of inventory to stock. Data-driven research must be upgraded with new technology to meet this real-time challenge. Supply chain managers need to use new and real-time data sets to create demand forecasts.

Port Congestion

One of the background factors affecting supply chain operations is port congestion, where the containers cannot unload due to maxed-out station capacity. Labor shortages, an increasing number of incoming containers, and competition among shipping companies have resulted in delays in the loading and unloading process. The backlog created by this congestion delays delivery for suppliers.

Evolving Consumer Demands

Customers expect ultra-fast delivery and superior customer experience. Businesses with an agile supply chain can only face these challenges with the power of automation.

Merchants have great profit margins with increased demand, but poor customer experience will eventually bring the business down. So, finding the right logistics partner is crucial for organizations looking to expand their resilience.

Digitization

Digital transformation and IoT are increasingly becoming common among global enterprises. Supply chain technologies are changing with artificial intelligence, on-demand delivery, electric vehicles, robotic warehouse management, drones, etc.

However, not all businesses have the capability and maturity to digitize and optimize their business operations instantly. As merchants adopt omnichannel selling, organizations must realign their technologies and migrate to new cloud platforms to meet evolving needs.

Restructuring Operations

Supplier management is changing as retailers expand their reach with global supplying partners. Creating new dynamic contracts and partnering with the latest shipping carriers must restructure business operations.

Identifying the right time to change and seamlessly transitioning to a new business model is challenging for many businesses. Maintaining optimal stock throughout this transition is critical to enjoy success with the transformation.

Best Practices For Supplier Relationship Management Strategy

Investing in digital technologies and onboarding suppliers is the first step to modernizing supplier relationship management. However, nurturing relationships with trusted suppliers and innovating together by building an environment of mutual trust is essential for business growth. Healthy partnerships result in better operational efficiency and improved financial outcomes.

Consider Suppliers As Partners

Organizations should start looking at suppliers as critical business partners. Suppliers are an important asset for any business, not just from a financial point of view. Your supplier management strategy should be integral to your business management strategy. Ensure that your suppliers have aligned their business goals with yours. Also, keeping them informed about organizational changes and maintaining consistent communication will bolster their loyalty and unlock partnership excellence.

Establish Effective Communication Channels

Building strong communication channels through digital SRM platforms is essential for successful supplier relationship management. Ensuring transparency in communication and facilitating two-way conversations will help suppliers feel valued in the relationship. Supplier managers must have the tools and skills to communicate easily with suppliers.

Pay Suppliers Timely

To strengthen supplier relationships, ensure you pay for the goods on time. Cash flow is important for suppliers as well. Prompt payments will ensure that you value the success of your supplier as well. Also, businesses will want to collaborate with customers who ensure timely payments. In case of payment issues, use your communication channel to communicate the delay and reasons to the suppliers to help them manage their cash flow.

Invest In People And Processes

Supplier relationship management can only bring value to the business if you focus on the human element. Creating a human-centric relationship with a dedicated supplier relationship manager is important to save time, money, and effort in managing a long list of suppliers. Also, investing in the right tools and equipping your supplier managers with the necessary skills will make them better at their jobs. Establishing proper supplier relationship processes and creating standards and guidelines will streamline workflows.

Monitor And Track Continuously

While managing a complex supply chain with different strategies based on supplier importance, establishing KPIs and metrics to measure performance is important. These metrics also help with risk mitigation. The analytics will help predict uncertainty in the supply chain so that businesses can make timely decisions. Monitoring and updating supplier management strategies is crucial to maintaining good supplier relationships.

Unlock Efficiency With Supplier Relationship Management Tools

Digital transformation integrating the latest digital technology tools, such as digital supply chain twins, AI and machine learning, advanced analytics, and task mining, is integral to business success.

A Gartner report shows that 95% of supply chains must reach changing conditions quickly, but only 7% can do so in real time. Even though supply chain leaders know what to do, there is a delay in executing responses because of legacy technology. The older technologies are unable to leverage real-time data, affecting business decisions.

Digitisation of supply chain operations enables access to real-time data, increasing end-to-end supply chain visibility. Businesses must also invest in skills to analyze the vast amount of data.

Only then can the business intelligence tools generate insights from the data to help in real-time decision execution. This adoption is expected to increase five times in the next 3-5 years.

To build a digital supply chain, businesses must assess their supply chain capabilities. They have to align their siloed supply chain practices with the digital vision to create a roadmap for the digital projects.

Prioritizing digital technology investments is crucial to expanding the supply chain's capabilities. The first step to building a digital supply chain is upgrading SRM practices using supplier relationship management software.

These tools streamline supplier operations and relationships, enabling organizations to become future-proof.

Some of the benefits of using SRM software are:

- Increase negotiation power by streamlining supplier operations

- Unlock hidden cost savings with quick onboarding and improved collaboration

- Expand sourcing reach by branching out to global suppliers

- Establish trust and control with a transparent SRM platform

- Automate supplier relationship workflows with pre-defined templates and automated reminders

- Streamline contracting tasks to save procurement costs

- Enhance supplier experience with improved communication

- Integrate advanced risk mitigation strategies to build resilience

- Ensure compliance with a unified SRM platform

Features To Look For In SRM Tools

The SRM tools automate supplier relationship workflows and collect supplier data to enable leaders to make proactive decisions. Ensuring the adaptability of these tools is important, as the procurement staff should be able to handle the steep learning curve. Bringing all aspects of supplier management under a unified platform will ensure that procurement staff know their responsibilities, timelines, tasks, and goals. Such a platform streamlines workflows and automates mundane tasks, enabling supplier relationship managers to operate effectively. Some of the important features to look for in SRM are:

Unified Supplier Portal

The tool must provide all information about a supplier or vendor at any time. Maintaining a single source of truth is important so that supplier catalogs, messages, resources, and communication channels are accessible from anywhere. The platform should also offer personalized dashboards for each supplier so that they can collaborate effectively with your business without the need for emails or phone calls.

Centralized Supplier Data Management

The SRM software should provide a unified storage platform to store invoices, contracts, activities, transactions, etc. Different dashboards should be available for users to complete their supplier management tasks. A tool with filters and search engines to look for data will enable quick and easy access to all information.

Real-Time Risk Management

Advanced SRM tools have built-in risk management strategies that will help you diversify your supplier sources and build resilience. It will also ensure that the suppliers pass compliance checks and alert you on issues with suppliers so you can find alternate solutions.

AI For Supplier Selections

Many SRM tools use cloud software to help you with supplier selection. These tools can automate supplier pre-qualifications and instantly provide a shortlisted supplier list. As these AI systems continue to learn, they can help you improve your supplier management strategy by matching you with the right suppliers based on your business needs in real-time.

Tech Stack Integration

Digitisation of businesses is not a singular task. Your business will simultaneously invest in different technologies and tools to optimize several operations. Your chosen SRM tool must integrate existing systems and new technologies and seamlessly optimize operations.

Analytics And Reporting

The primary purpose of digitizing SRM operations is to gain insights from data. Your chosen tool should equip you with data analytics that BI tools can utilize to generate new insights. Tools that support report generation with a few clicks will enable supply managers to make data-driven business decisions.

Conclusion

Strategic planning to build a dynamic digital supply chain emphasizing the role of suppliers requires a fundamental shift in the SRM approach. Taking control of the supply chain and incorporating resilience is essential to future-proofing your business.

Building stronger supplier relationships is possible with a digital SRM system that optimizes and streamlines workflows. The suppliers should also feel confident innovating so your business can utilize their skills to grow.

India Index is revolutionizing B2B supply chain procurement by building strategic partnerships with Indian suppliers. Automate your supply chain operations and benefit from transparent sourcing using our services.

Discover the India Index platform to partner with resilient suppliers to meet your business expansion needs.

Was this article helpful? 💡