Supply Chain

Understanding Supply Chain Management Operations

Gain insights into supply chain management operations with our comprehensive guide. Understand key supply chain concepts, processes, and best practices for efficient operations. Learn about supply chain planning, sourcing, logistics, and how to optimize your supply chain.

By India Index

7 min read

Introduction

The supply chain transforms raw materials into finished products to deliver to customers. It is a complicated network containing numerous organizations involved in various activities.

Everyone in the supply chain, including suppliers, manufacturers, distributors, retailers, and customers, must work harmoniously to ensure the final product reaches the customers.

In this ecosystem, supply chain management operations involve procurement, management, storage of raw materials, movement-related activities, and delivery and storage of finished goods. It encompasses manufacturing and service industries.

The essence of supply chain and operations management is enabling organizations to increase their operational efficiency and effectiveness while reducing overall expenses. Most of the operations related to supply chain management happen outside of the organization. Organizations must design, plan, execute, control, and monitor all supply chain activities and optimize the workflow to maximize value.

This article will cover the concept of supply chain management operations in detail, including why its optimization is important, its basic components, needs, and challenges. The article even includes the latest trends for the same.

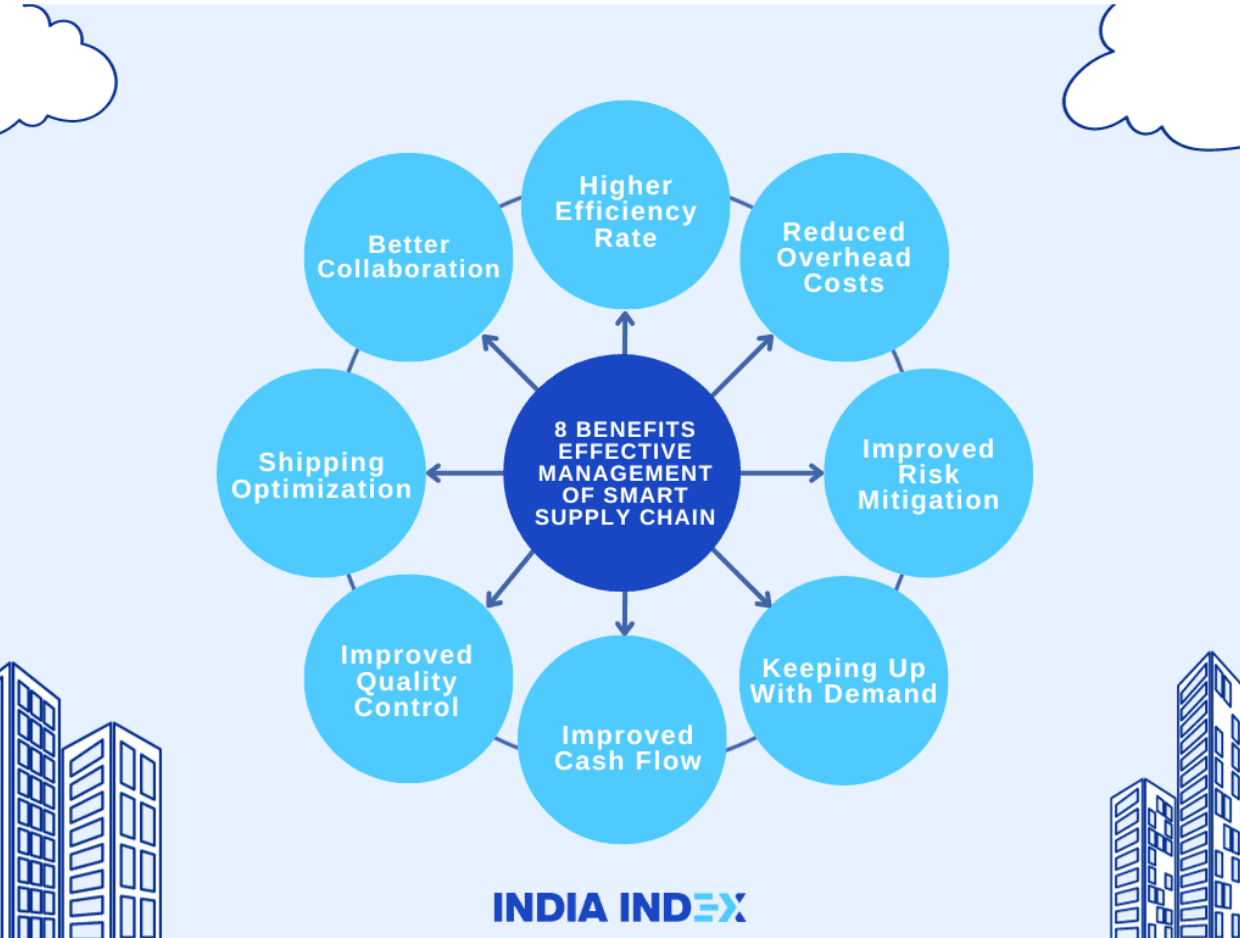

Why Optimize Supply Chain Management Operations?

The competitiveness and performance of an organization are determined by its supply chain’s operational efficiency. In the modern business landscape, enterprises must stay on top of consumer needs and control the movement of resources throughout the supply chain to deliver value to their clients.

More than 83% of organizations believe that supply chains play a major role in improving the customer experience. The key reasons why organizations must optimize supply chain operations are:

- Cost Optimization

An effective supply chain management system reduces operational costs by optimizing processes, minimizing waste, improving resource allocation, and realizing cost savings. It can directly result in higher profitability for businesses.

- Enhanced Customer Satisfaction

Optimized and sophisticated supply chain management will improve the timely and reliable delivery of goods to customers. Modern-day customers expect super-fast delivery, and a well-managed supply chain can improve customer satisfaction.

- Better Inventory Control

An integral part of operations and supply chain management is inventory management, which prevents overstocking, reduces carrying costs, and minimizes the risk of obsolete stock. Proper inventory management ensures that products in demand are always available, avoiding stockouts.

- Market Responsiveness

Agile supply chain management operations will enable organizations to respond quickly to changing market conditions. It will help in predicting emerging trends and demand fluctuations. Adaptability will enable businesses to seize opportunities as they arise.

- Effective Quality Control

Optimal supply chain management also helps meet quality standards during production and delivery. It will help in delivering high-quality products to customers.

- Efficient Risk Mitigation

Supply chain management operations also involve risk assessment and mitigation strategies. Organizations can use advanced tools to predict disruptions affecting business operations like natural disasters, supply chain disorders, etc. Supply chain leaders can then take proactive measures to overcome these risks.

- Global Expansion

Modern supply chain operations enable companies to expand their reach into international markets. Cross-border logistics facilitate international trading.

- Sustainability

Due to climate change pressure, organizations are exploring more sustainability initiatives in the logistics sector. Effective management of supply chain operations will enable organizations to reduce their carbon footprint by sourcing sustainable materials and optimizing transportation routes.

- Spark Innovation

Digitization of supply chain management operations will allow organizations to form strategic partnerships with suppliers and partners. Efficient collaboration will encourage these partners to innovate together to share cost savings.

- Improve Financial Performance

Savings realized with supply chain management will improve the company's financial performance. It will also help optimize cash flow, reduce working capital, and increase profitability.

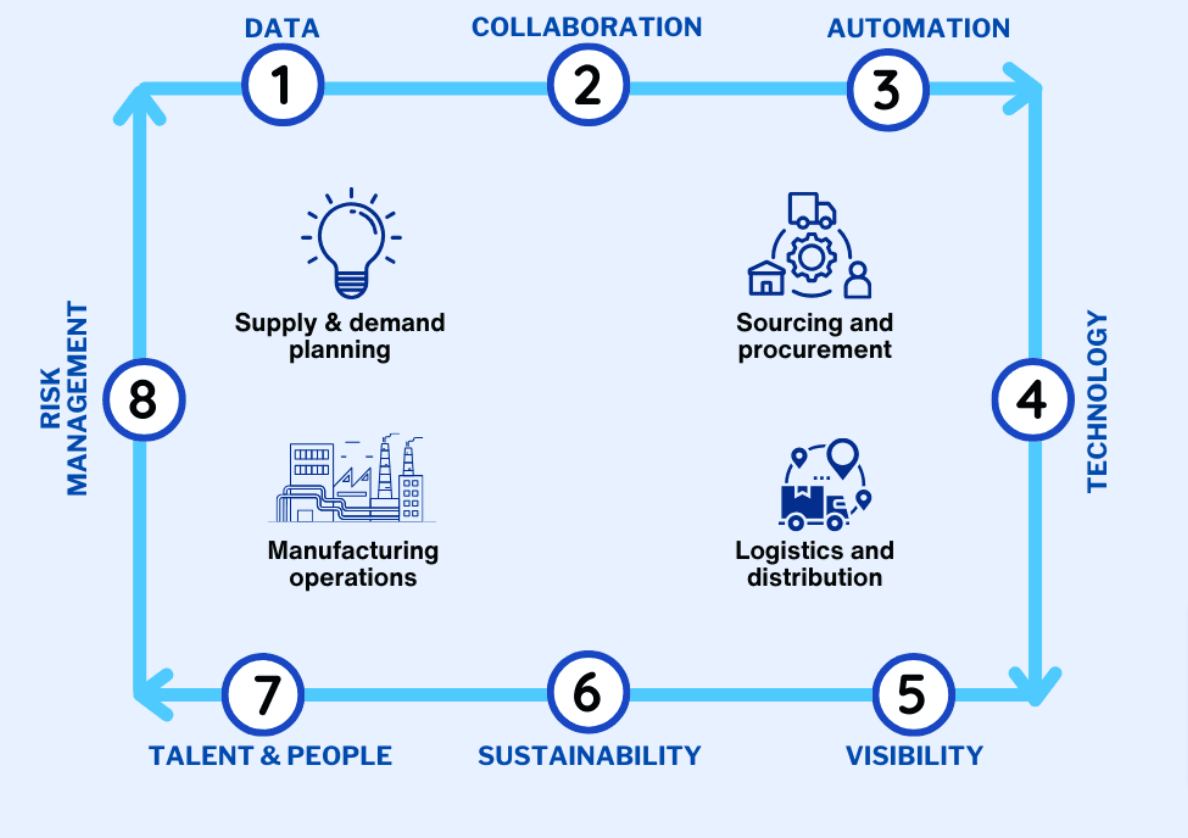

Basic Components of Supply Chain Management Operations

Depending on the nature of the business, the workflow of supply chain management operations varies. However, the common components are as follows:

- Engineering – Designing a new product that the customers need to solve problems.

- Planning – Forecasting demand, setting inventory levels, and developing efficient strategies to meet customer requirements.

- Sourcing and Procurement - Identifying and choosing suppliers, negotiating terms, and establishing necessary contracts with vendors to procure materials, products, or components.

- Inbound Logistics – Purchasing goods from services, communicating with suppliers, and ensuring that the required raw materials are received in a timely manner.

- Manufacturing – Making products using procured materials and ensuring the highest quality to meet customer demands. It also involves the management of inventory levels.

- Fulfilment and Delivery – Transporting products to the customers using the quickest and most cost-effective routes.

- Service Management – Maintaining, managing, and improving products to ensure customer satisfaction.

In a supply chain workflow, the above processes are executed linearly. The output from the previous process becomes the input for the next process. So, in a supply chain, all the entities are interdependent. This linear approach is not suitable anymore for modern business processes that are varied and complex. The demanding business environment expects supply chain operations to be agile. A robust workflow will ensure that disruptions in any part of the supply chain will not bring the entire business to a grinding halt.

Challenges in Supply Chain Management Operations

The modern business landscape is highly demanding, and traditional supply chain operations will not work anymore. Organizations will be able to double their profits by simply reducing supply chain expenses from 9% to 4%. Some of the key challenges that supply chain leaders face are:

Complex Global Networks

While globalization expands the market reach of businesses, it brings its own set of challenges. Supply chain leaders have to connect with international suppliers and comply with international regulations and logistics standards, which can be overwhelming.

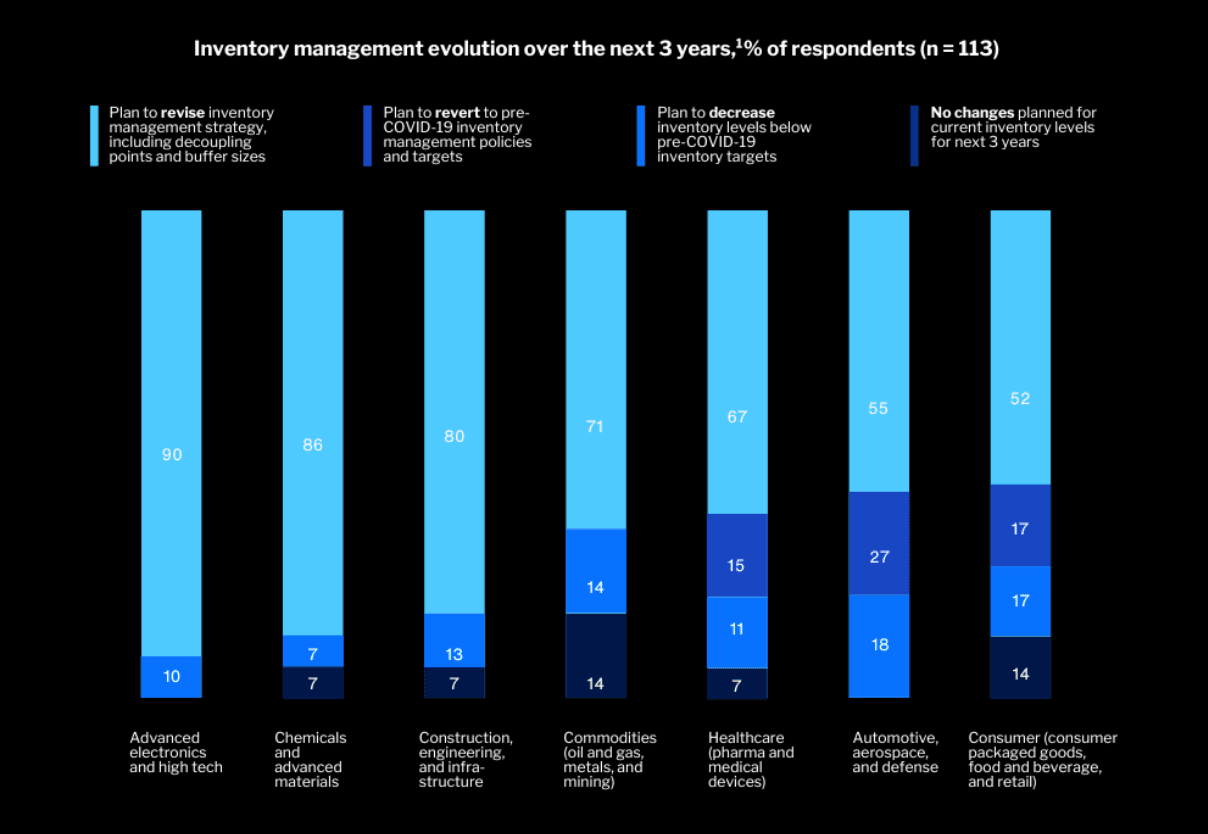

Supply Chain Disruptions

The geopolitical and economic changes in the world result in massive disruptions in the supply chain industry. Natural disasters, too, can wreak havoc on delivery times. Unexpected events like the global COVID-19 pandemic can disrupt the entire operational workflow. Only resilient and flexible supply chains can overcome such disruptions in the future.

Technology Integration

Technology integration and digitization are essential for supply chain management operations to stay competitive. New technologies such as blockchain, IoT, AI, and data analytics can transform supply chain operations. However, adopting such technologies is complex, expensive, and resource-intensive. Integrating modern systems with existing legacy architecture is also challenging.

Sustainability

Every industry is under pressure to adopt sustainability practices. The supply chain management and logistics industry is responsible for most carbon emissions. The logistics operators are expected to reduce the environmental impact by managing waste. Identifying sustainable suppliers, optimizing transportation, implementing sustainability practices, and enabling green supply management operations pose additional challenges.

Regulatory Compliance

As companies expand their supply chain operations across borders, they must comply with numerous trade regulations, labor laws, and environmental laws. Adhering to legal requirements and ensuring compliance with regularity requirements are major hurdles for global supply chain management.

eCommerce and Last-mile Delivery

The increase in eCommerce trends and D2C business operations adds to the supply chain challenges of organizations. Meeting evolving customer demands and optimizing last-mile delivery will also become integral to future supply chain management operations. Fast and cost-effective delivery will become the focus of organizations wanting to increase profitability.

Talent Shortage

Integrating technology and balancing supply chain operations require skilled supply chain professionals. The talent shortage in this evolving industry makes it difficult for businesses to hire and retain talent with expertise and experience.

Data Security and Privacy

The use of technology in supply chain operations means that vast volumes of crucial and sensitive personal and financial data are stored in distributed systems. The privacy and security of such data are at risk as the number of cybersecurity attacks increases.

Need for Digitisation in Supply Chain Management Operations

Around 55% of genuine OEM manufacturers will restructure their supply chain operations by April 2026. Effective supply chain management operations will enable organizations to capitalize on opportunities for innovation, sustainability, and efficiency. Adapting to a rapidly changing market is essential for supply chain operations to be successful. Procurement has become the core of several executive committee-level decisions.

Over the past few years, companies have made structural changes to their supply chain networks. Improving visibility across supply chains is a priority across industries. Also, organizations now focus on improving demand and supply planning for cost optimization. Technological advancements and evolving customer demands increase complexity and uncertainty in supply chain operations. Digitization can unlock the potential of resilient supply chains to make the entire process sustainable and efficient.

While digitization is the key to developing a resilient, flexible, and robust supply chain, the process is resource-intensive. It requires technical skills, advanced analytics, and cross-functional collaboration to digitize the operations. Organizations must invest in creating the roadmap for end-to-end supply chain digitization to support business growth. 63% of organizations have no technology systems for monitoring supply chain performance. In the future, the cost of not adopting digitization will erode an organization's profits. Some of the advantages of digitizing the supply chain management process are:

Automation Opportunities

Automation effectively reduces manual labor and reduces the time and effort of the administrative team. Automating workflows will enable the supply chain staff to focus on core business tasks. It also streamlines supply chain processes, reducing the time spent on each operation. Apart from speeding up processes, automation also eliminates human errors.

Improved Connectivity

Emails and spreadsheets for managing vendor and supplier relationships are obsolete as modern-day suppliers have moved on to supply chain management platforms. A unified interface and cloud-based software will improve connectivity and collaboration among all the stakeholders. It will also improve communication and file sharing to expedite the procurement process. Establishing a single source for all supply chain data will improve data integrity.

Data-driven Decision-making

In the highly competitive business world, leaders must make accurate decisions quickly. A digital supply chain will empower leaders with insights and analytics to make agile business decisions. You can develop profitable strategies for any scenario using predictive data and real-time information. Incorporating AI and ML technologies will help businesses stay on top of the latest trends in the industry.

Road Map for Digitization of Supply Chain Management Operations

Across enterprises, 82% of supply chain leaders plan to invest more in digital capabilities in their supply chain operations. However, less than half of those leaders understand the clear goals of the digital transformation roadmap.

Depending on the complexity of the supply chains, some of them may be slow to react. Businesses must upgrade their supply chain management strategy as an effective way to mitigate supply chain risk. Creating effective roadmaps is essential to planning and centralizing supply chain operations.

Identify Supply Chain Objectives

Digitization can benefit an organization that completely understands the need for such a transformation. Defining and documenting supply chain objectives that make digital optimization necessary is the first step for the roadmap. This requires a proper understanding of the digital business ambitions of the organization.

Determine Changes in Capabilities

The next step is to assess the current status of supply chain operations and identify the capabilities that enable digital operations. Every step of the supply chain will be at different levels of digital maturity. The goal should be to bring uniformity to digital operations so that the supply chain staff can collaborate effectively.

Prioritize Technology Investments

Digital transformation is only possible with significant technological investment. Understanding emerging technologies and adapting such technologies to suit the demands of the organization is crucial to expanding supply chain capabilities.

Address Technology Gaps in the Supply Chain

Understanding existing technological capabilities and identifying gaps is essential to creating a plan. The supply chain manager must hire technology talent to implement the latest technologies, such as AI, ML, IoT, etc.

Determine a Governance Framework

Digitization is not a one-step process. It is an ongoing transformation path that involves upgrading to the latest technologies. Migrating to the cloud is also essential for supply chain operations to optimize operations cost-effectively. It will also enable businesses to adopt ESG (Environmental, Social, and Governance) initiatives. Setting up a governance framework is useful for decision-making involving all the stakeholders. Communicating transformation objectives and roadmaps will ensure that the staff is on board.

Moving Forward With Intelligent Supply Chains

The intelligent supply chain enables organizations to solve complicated and persistent challenges in the dynamic ecosystem. Only 46% of organizations have the most needed supply chain resiliency and visibility to respond to disruptions effectively.

Building an integrated, responsive, and collaborative supply chain ecosystem leveraging the latest digital technologies is integral to a seamless supply chain management workflow. Incorporating disruptive technologies such as AI can improve resilience, service excellence, cost-effectiveness, long-term sustainability, and optimized inventory.

360-degree Visibility

Digitization enhances the visibility of supply chain operations, but an intelligent supply chain will provide end-to-end strength. It leverages real-time data obtained from connected devices using IoT. It will enable decision-makers to gain deeper insights into supply management operations and allow for maximum scalability. Leaders can make effective contingency plans with an adaptive supply chain that can respond actively to unforeseen events, delayed shipments, and other disruptions.

Predictive Analysis

While external events can’t be controlled, predictive analysis will be useful in predicting events within the organization that can cause supply chain disruptions. It will allow leaders to adopt proactive strategies to tackle predicted disruptions. This will help businesses avoid potential setbacks that can disrupt supply chain efficiency.

Real-time Collaboration

Resilient and adaptable supply chains will improve execution and planning for network partners. Organizations can easily navigate multiple supplier partners and diversify their sources to improve procurement processes. Monitoring changes in demand and supply will enable corporations to collaborate with suppliers to reduce supply chain risks. It will help optimize freight movements with real-time carrier management.

Identify Patterns and Anomalies

The use of AI in supply chain management operations will help uncover new patterns and anomalies from the vast amount of data. Supply chain operations involve collecting massive amounts of data on data siloes. Decentralized data storage using cloud operations and AI tools will help leaders create actionable insights based on the data. It can help uncover patterns and anomalies that can transform business processes.

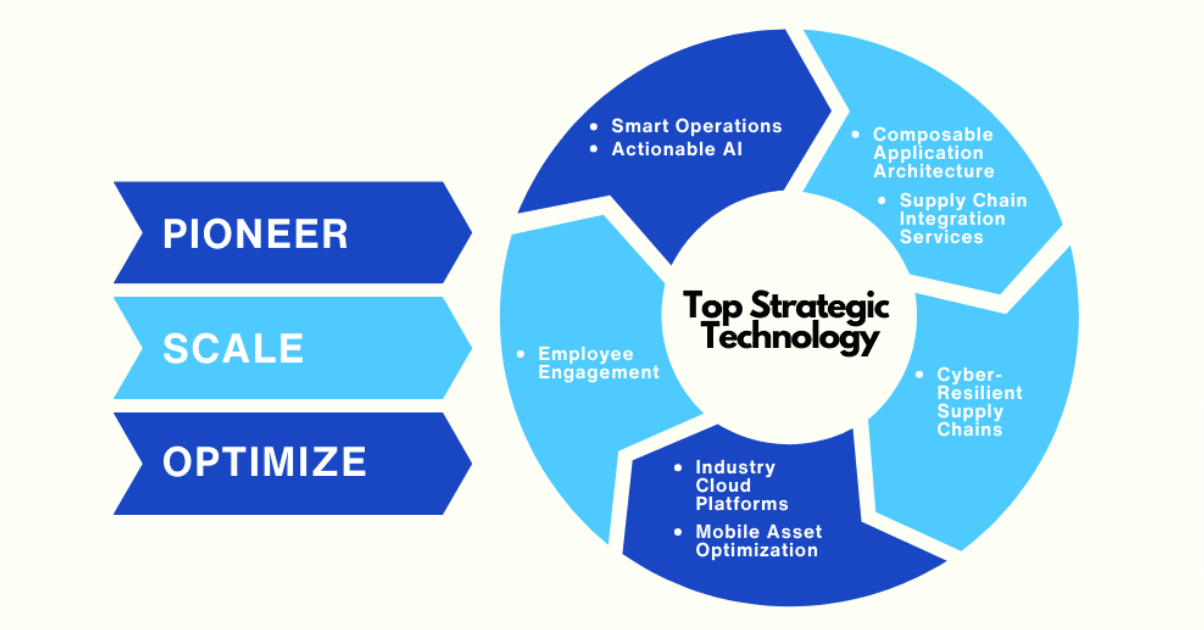

Latest Supply Chain Technology Trends

A Gartner report shows that 73% of the supply chain IT budget will be spent on growth and performance. Leaders anticipate that funding technology investments will be a real possibility as companies focus on achieving supply chain targets.

The latest technology trends in supply chain operations are:

- Actionable AI

Technology leaders work on building actionable AI that can enable data-driven decisions using problem-solving techniques. Humans can also be involved in the loop for validating the AI decisions. The AI model can learn from the existing patterns based on past experiences and decisions. This is crucial to adapting to changing circumstances in the real world. Based on new data, these AI solutions can learn and retrain to adapt to the changing runtime environment.

- Smart Operations

With new technology innovations, core operational capabilities such as manufacturing, logistics, warehousing, and transportation can be upgraded to smart operations. Distributed processes and data are useful in building smart systems that transform businesses.

- Mobile Asset Optimization

Enterprises increasingly use mobile assets to improve supply chain flexibility. These assets include business process software, operational research techniques, and sensory technologies. They provide business intelligence tools and information useful in building smart robots that can take over warehouse management. Introducing transportation visibility platforms optimizes carrier operations by increasing collaboration between carriers, shippers, and other logistics providers.

- Cloud Platforms

Cloud adoption involves migrating supply chain management operations to the cloud using SaaS, PaaS, and IaaS services that cater to the specific functionality of the supply chain operations. These platforms are inherently agile and scale up business capabilities based on requirements. Migrating business platforms to the cloud allows technology innovation, adding value to the enterprise technology architecture.

- Employee Engagement

As the supply chain evolves, people are recognized as an organization's biggest asset. Employee engagement tools will help organizations focus on frontline workers' performance. Improving retention and satisfaction of the supply chain workforce will enable better management of operations. Incorporating mixed reality and wearable devices increases collaboration and improves job efficiency.

- Application Architecture

Supply chain applications in the modern era must follow the design principles of autonomy, modularity, and orchestration to satisfy business needs. These software components make business processes efficient and scalable.

- Cyber Resilience

As advanced supply chains move to the cloud and embrace technology, cybersecurity becomes important in the digital supply chain. Digital connectivity exposes enterprise architecture to cybersecurity risks and vulnerabilities. However, improving cyber resilience involves using tools, processes, and methods to mitigate cyber security risks in the heterogeneous supply chain ecosystem.

- Supply Chain Integration

Modernizing supply chain operations can be successful only if technology platforms are properly integrated. Applications involved in supply chain management must work together in an integrated environment to manage overall operations. In the interconnected world, system interoperability is critical to enabling process optimization.

Best Practices for Supply Chain Management Operations

The volatile market, evolving consumer demands, disrupted logistics, labor shortages, and geopolitical events continue to threaten supply chain management, and agile businesses will become frontrunners.

Elastic logistics is the need of the hour for futuristic supply chains. Cloud technologies and AI will enable organizations to improve the visibility and transparency of their supply chain operations. Some of the best practices that can help organizations navigate volatility and uncertainty are:

- Build agile ecosystems by planning and collaborating with suppliers, manufacturers, vendors, and partners across wide geographical areas

- Manage supply chain risks with risk assessment tools, strategic planning, and robust continuity plans

- Leverage real-time data and integrate BI tools to derive supply chain analytics

- Integrate flexible contracts that can be modified to reflect customer demands and evolving market conditions

- Incorporate proactive practices to anticipate and adapt supply chain operations to respond to threats and disruptions

- Innovate to reduce waste and energy consumption to improve green logistics practices

Conclusion

Traditional and linear supply chains are not useful in dynamic business environments. Analyzing risks and rebalancing supply chain opportunities are crucial for businesses adopting the cloud to manage supply chain operations better. Sustainability will be a key factor determining the agile practices adopted by organizations that move towards on-shoring and near-shoring for supply chain management operations.

Diversifying suppliers and increasing inventory reserves are crucial for forward-looking supply chains. Supply chain leaders also emphasize customer centricity as the D2C business model grows. Automation and AI-powered supply chain operations will help build frictionless supply chains that propel business growth.

India Index is pioneering B2B supply chain procurement from India, enabling supply chain resilience for global businesses by partnering with Indian suppliers.

Elevate supply chain practices and experience a transparent sourcing process with India Index platform. Explore our platform and connect with reliable and robust supply chain partners for your needs.

Was this article helpful? 💡